Cookie Policy

MagnetSearcher stores cookies on your computer to provide more personalized services to you, both on this website and through other media. By using this website, you consent to the cookies we use and our Privacy Policy.

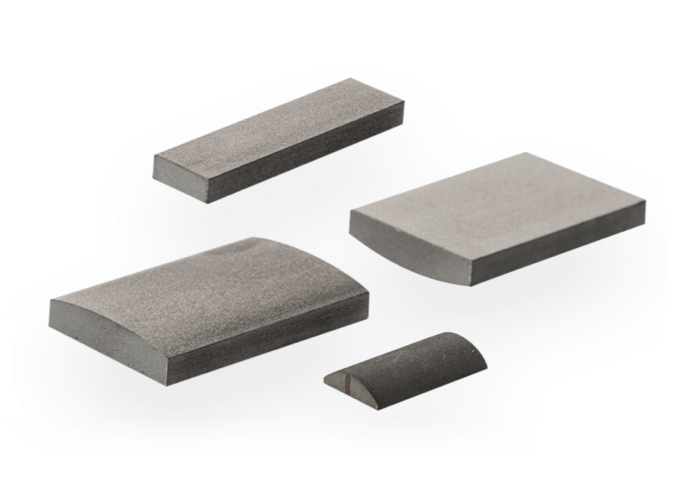

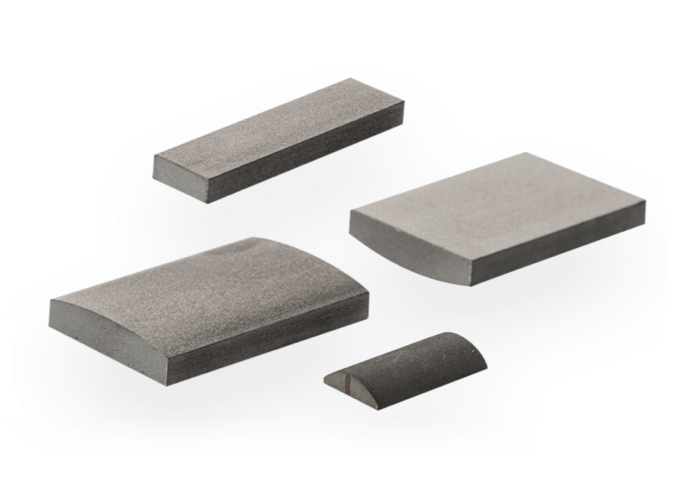

Samarium cobalt (SmCo) magnets are the first commercially viable rare earth permanent magnet material since 1960s and considered to still be the premium material for many high performance applications today. SmCo magnets have particularly high coercivities with simultaneous high saturation polarization and excellent temperature stability. Additionally, the corrosion resistance of SmCo magnets are significantly high, usually no coating necessary.

SmCo magnets can be divided to two categories sintered SmCo and bonded SmCo by processing technology. There are two generations of sintered SmCo magnets, the first is 1:5 SmCo (SmCo5) and the second is 2:17 SmCo (Sm2Co17). Ductibility of SmCo5 magnets is excellent. It is easy to be machined into disc, ring and complex shapes. Sm2Co17 have a low temperature coefficient. The change of flux density can be lower than 2% per 100 °C.

SmCo magnets are widely used in servo motors, automotive applications (e.g. sensors...), high end sport cars, aviation. Sintered Samarium Cobalt magnets are still playing irreplaceable roles in high temperature applications which are not possible for sintered Neodymium magnet.

| Grade |

Residual magnetic flux density Br |

Coercive force HcB |

Intrinsic coercive force HcJ |

Maximum energy product (BH)max |

Work Temperature Tw |

Average Temperature Coefficients of Br | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T | KGs | KA/m | KOe | KA/m | KOe | kJ/m³ | MGOe | ℃ | %/℃ | ||

| Sm2Co17 | YXG24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1990 | ≥25.0 | 175-191 | 22-24 | 350 | -0.025 |

| YXG26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1990 | ≥25.0 | 191-207 | 24-26 | 350 | -0.030 | |

| YXG28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1990 | ≥25.0 | 207-223 | 26-28 | 350 | -0.035 | |

| YXG30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1990 | ≥25.0 | 223-239 | 28-30 | 350 | -0.035 | |

| YXG32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1990 | ≥25.0 | 231-255 | 29-32 | 350 | -0.035 | |

| YXG33H | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1990 | ≥25.0 | 239-263 | 30-33 | 350 | -0.035 | |

| YXG22 | 0.93-0.97 | 9.3-9.7 | 676-740 | 8.5-9.3 | ≥1433 | ≥18 | 160-183 | 20-23 | 300 | -0.020 | |

| YXG24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥1433 | ≥18 | 175-191 | 22-24 | 300 | -0.025 | |

| YXG26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥1433 | ≥18 | 191-207 | 24-26 | 300 | -0.030 | |

| YXG28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥1433 | ≥18 | 207-223 | 26-28 | 300 | -0.035 | |

| YXG30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥1433 | ≥18 | 223-239 | 28-30 | 300 | -0.035 | |

| YXG32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥1433 | ≥18 | 231-255 | 29-32 | 300 | -0.035 | |

| YXG33 | 1.12-1.16 | 11.2-11.6 | 845-890 | 10.6-11.2 | ≥1433 | ≥18 | 239-263 | 30-33 | 300 | -0.035 | |

| YXG35 | 1.16-1.20 | 11.6-12.0 | 868-908 | 10.9-11.4 | ≥1433 | ≥18 | 255-278 | 32-35 | 300 | -0.035 | |

| YXG26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 300 | -0.035 | |

| YXG28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 300 | -0.035 | |

| YXG30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 300 | -0.035 | |

| YXG32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 300 | -0.035 | |

| YXG24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8/12 | 175-191 | 22-24 | 250 | -0.025 | |

| YXG26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8/12 | 191-207 | 24-26 | 250 | -0.035 | |

| YXG28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8/12 | 207-220 | 26-28 | 250 | -0.035 | |

| YXG30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8/12 | 220-240 | 28-30 | 250 | -0.035 | |

| YXG32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8/12 | 230-255 | 29-32 | 250 | -0.035 | |

| LTC18 | 0.84-0.89 | 8.4-8.9 | 629-668 | 7.9-8.4 | ≥1433 | ≥18 | 135-151 | 17-19 | 300 | -0.001 | |

| LTC20 | 0.89-0.94 | 8.9-9.4 | 660-708 | 8.3-8.9 | ≥1433 | ≥18 | 151-167 | 19-21 | 300 | -0.007 | |

| LTC22 | 0.94-0.98 | 9.4-9.8 | 692-740 | 8.7-9.3 | ≥1433 | ≥18 | 167-183 | 21-23 | 300 | -0.010 | |

| HT400(24) | 0.99-1.04 | 9.9-10.4 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 183-199 | 23-25 | 400 | -0.035 | |

| HT400(22) | 0.94-0.99 | 9.4-9.9 | 700-748 | 8.8-9.4 | ≥1830 | ≥23 | 167-183 | 21-23 | 450 | -0.035 | |

| HT400(20) | 0.89-0.94 | 8.9-9.4 | 660-708 | 8.3-8.9 | ≥1830 | ≥23 | 151-167 | 19-21 | 500 | -0.035 | |

| SmCo5 | YX16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 250 | -0.050 |

| YX18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-8.8 | 1194-1830 | 15-23 | 127-143 | 16-18 | 250 | -0.050 | |

| YX20 | 0.90-0.94 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 250 | -0.050 | |

| YX22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-9.4 | 1194-1830 | 15-23 | 160-175 | 20-22 | 250 | -0.050 | |

| YX24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 250 | -0.050 | |

| YX16s | 0.79-0.84 | 7.9-8.4 | 620-660 | 7.8-8.3 | ≥1830 | ≥23 | 118-135 | 15-17 | 250 | -0.035 | |

| YX18s | 0.84-0.89 | 8.4-8.9 | 660-700 | 8.3-8.8 | ≥1830 | ≥23 | 135-151 | 17-19 | 250 | -0.040 | |

| YX20s | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-9.2 | ≥1830 | ≥23 | 150-167 | 19-21 | 250 | -0.045 | |

| YX22s | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-9.5 | ≥1830 | ≥23 | 167-183 | 21-23 | 250 | -0.045 | |

| YX24s | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥1830 | ≥23 | 183-199 | 23-25 | 250 | -0.045 | |

| LTC(YX10) | 0.62-0.66 | 6.2-6.6 | 485-517 | 6.1-6.5 | ≥1830 | ≥23 | 75-88 | 9.5-11 | 300 |

20-100℃ +0.0125 100-200℃ +0.0087 200-300℃ +0.0007 |

|

| Grade |

Residual magnetic flux density Br |

Coercive force HcB |

Intrinsic coercive force HcJ |

Maximum energy product (BH)max |

Average Temperature Coefficients of Br | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| mT | Gs | KA/m | KOe | KA/m | KOe | kJ/m³ | MGOe | %/℃ | ||

| Bonded SmCo | SCZ-4T | 380-420 | 3.8-4.2 | 200-280 | 2.5-3.5 | 640-1030 | 8.0-13.0 | 28-36 | 3.5-4.5 | -0.030 |

| SCZ-5T | 410-540 | 4.1-5.4 | 265-360 | 3.3-4.5 | 640-1200 | 8.0-15.0 | 36-44 | 4.5-5.5 | -0.030 | |

| SCZ-9 | 610-660 | 6.1-6.6 | 415-480 | 5.2-6.0 | 640-1200 | 8.0-15.0 | 68-75 | 8.5-9.5 | -0.030 | |

| SCZ-11 | 640-720 | 6.4-7.3 | 430-510 | 5.4-6.4 | 640-1200 | 8.0-15.0 | 76-88 | 9.5-11.0 | -0.030 | |

The above mentioned data of magnetic properties and physical properties are given at room temperature (20℃).

The max working temperature of magnet is changeable due to length-diameter ratio and other environment factors.

Additional grades are available. Please contact us for information.

Following data are only for reference when designing and selecting materials, not as product acceptance standards.

| Item | Unit | SmCo5 | Sm2Co17 | |

|---|---|---|---|---|

| Recoil Permeability μrac | μrec | — | 1.00-1.05 | 1.00~1.10 |

| Curie Temperture Tc | Tc | ℃ | 1000 | 1100 |

| Density | D | g/cm3 | 8.3 | 8.4 |

| Vickers Hardness(HV) | Hv | MPa | 450~500 | 550~600 |

| Compressive Strength | δc | MPa | 1000 | 800 |

| Bending Strength | δb | MPa | 150-180 | 130-150 |

| Tensile Strength | δt | MPa | 400 | 350 |

| Electrical Resistivity | ρ | Ω·m | 5~6x10-5 | 8~9x10-5 |

| Coefficient of Thermal Expansion | α | 10-6 /℃ | C⊥: 12 | C⊥: 11 |

| C∥: 6 | C∥: 8 | |||