Cookie Policy

MagnetSearcher stores cookies on your computer to provide more personalized services to you, both on this website and through other media. By using this website, you consent to the cookies we use and our Privacy Policy.

Neodymium iron boron (NdFeB) magnets offer the highest energy product of any material today and are available in a wide range of shapes, sizes and grades. Neodymium magnets can be divided into sintered Neodymium magnets and bonded Neodymium magnets base on the manufacturing process. NdFeB magnets can be found in a variety of applications including high performance motors, brushless DC motors, magnetic separation, magnetic resonance imaging, sensors and loudspeakers. Neodymium magnets have made possible smaller and more advanced electronic devices than ever before.

Sintered Neodymium magnets have excellent permanent magnetic properties and high performance price ratio compared with traditional permanent magnets. Sintered Neodymium magnets mainly comprised of iron, neodymium, boron and other trace elements. They are widely used in the fields of transportation, energy, communications, intelligence manufacture, intelligent drive.

| Grade | Residual magnetic flux density Br |

Coercive force HcB |

Intrinsic coercive force HcJ |

Maximum energy product (BH)max |

Work Temperature Tw |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| T | kGs | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | ℃ | ||

| Range | Min | Min | Range | Reference Value | ||||||

| N | N30 | 1.08-1.13 | 10.8-11.3 | 796 | 10.0 | 955 | 12 | 223-247 | 28-31 | 80 |

| N33 | 1.13-1.17 | 11.3-11.7 | 836 | 10.5 | 955 | 12 | 247-271 | 31-34 | 80 | |

| N35 | 1.17-1.22 | 11.7-12.2 | 860 | 10.8 | 955 | 12 | 263-287 | 33-36 | 80 | |

| N38 | 1.22-1.25 | 12.2-12.5 | 860 | 10.8 | 955 | 12 | 287-310 | 36-39 | 80 | |

| N40 | 1.25-1.28 | 12.5-12.8 | 860 | 10.8 | 955 | 12 | 302-326 | 38-41 | 80 | |

| N42 | 1.28-1.32 | 12.8-13.2 | 860 | 10.8 | 955 | 12 | 318-342 | 40-43 | 80 | |

| N45 | 1.32-1.38 | 13.2-13.8 | 860 | 10.8 | 955 | 12 | 342-366 | 43-46 | 80 | |

| N48 | 1.38-1.42 | 13.8-14.2 | 860 | 10.8 | 955 | 12 | 366-390 | 46-49 | 80 | |

| N50 | 1.40-1.45 | 14.0-14.5 | 860 | 10.8 | 955 | 12 | 382-406 | 48-51 | 80 | |

| N52 | 1.43-1.48 | 14.3-14.8 | 836 | 10.5 | 955 | 12 | 398-422 | 50-53 | 80 | |

| N54 | 1.45-1.49 | 14.5-14.9 | 836 | 10.5 | 876 | 11 | 406-438 | 51-55 | 80 | |

| N56 | 1.48-1.52 | 14.8-15.2 | 836 | 10.5 | 876 | 11 | 414-454 | 52-57 | 80 | |

| M | N30M | 1.08-1.13 | 10.8-11.3 | 796 | 10.0 | 1114 | 14 | 223-247 | 28-31 | 100 |

| N33M | 1.13-1.17 | 11.3-11.7 | 836 | 10.5 | 1114 | 14 | 247-271 | 31-34 | 100 | |

| N35M | 1.17-1.22 | 11.7-12.2 | 868 | 10.9 | 1114 | 14 | 263-287 | 33-36 | 100 | |

| N38M | 1.22-1.25 | 12.2-12.5 | 899 | 11.3 | 1114 | 14 | 287-310 | 36-39 | 100 | |

| N40M | 1.25-1.28 | 12.5-12.8 | 923 | 11.6 | 1114 | 14 | 302-326 | 38-41 | 100 | |

| N42M | 1.28-1.32 | 12.8-13.2 | 955 | 12.0 | 1114 | 14 | 318-342 | 40-43 | 100 | |

| N45M | 1.32-1.38 | 13.2-13.8 | 995 | 12.5 | 1114 | 14 | 342-366 | 43-46 | 100 | |

| N48M | 1.38-1.42 | 13.8-14.2 | 1027 | 12.9 | 1114 | 14 | 366-390 | 46-49 | 100 | |

| N50M | 1.40-1.45 | 14.0-14.5 | 1033 | 13.0 | 1114 | 14 | 382-406 | 48-51 | 100 | |

| N52M | 1.43-1.48 | 14.3-14.8 | 1050 | 13.2 | 1114 | 14 | 398-422 | 50-53 | 100 | |

| N54M | 1.45-1.49 | 14.5-14.9 | 1050 | 13.2 | 1114 | 14 | 406-438 | 51-55 | 100 | |

| H | N30H | 1.08-1.13 | 10.8-11.3 | 796 | 10.0 | 1353 | 17 | 223-247 | 28-31 | 120 |

| N33H | 1.13-1.17 | 11.3-11.7 | 836 | 10.5 | 1353 | 17 | 247-271 | 31-34 | 120 | |

| N35H | 1.17-1.22 | 11.7-12.2 | 868 | 10.9 | 1353 | 17 | 263-287 | 33-36 | 120 | |

| N38H | 1.22-1.25 | 12.2-12.5 | 899 | 11.3 | 1353 | 17 | 287-310 | 36-39 | 120 | |

| N40H | 1.25-1.28 | 12.5-12.8 | 923 | 11.6 | 1353 | 17 | 302-326 | 38-41 | 120 | |

| N42H | 1.28-1.32 | 12.8-13.2 | 955 | 12.0 | 1353 | 17 | 318-342 | 40-43 | 120 | |

| N45H | 1.32-1.36 | 13.2-13.6 | 995 | 12.5 | 1353 | 17 | 342-366 | 43-46 | 120 | |

| N48H | 1.38-1.42 | 13.8-14.2 | 1027 | 12.9 | 1353 | 17 | 366-390 | 46-49 | 120 | |

| N50H | 1.40-1.45 | 14.0-14.5 | 1043 | 13.1 | 1353 | 17 | 382-406 | 48-51 | 120 | |

| N52H | 1.43-1.48 | 14.3-14.8 | 1059 | 13.3 | 1353 | 17 | 398-422 | 50-53 | 120 | |

| N54H | 1.45-1.49 | 14.5-14.9 | 1059 | 13.3 | 1273 | 16 | 406-446 | 51-55 | 120 | |

| SH | N30SH | 1.08-1.13 | 10.8-11.3 | 804 | 10.1 | 1592 | 20 | 223-247 | 28-31 | 150 |

| N33SH | 1.13-1.17 | 11.3-11.8 | 844 | 10.6 | 1592 | 20 | 247-271 | 31-34 | 150 | |

| N35SH | 1.17-1.22 | 11.7-12.2 | 876 | 11.0 | 1592 | 20 | 263-287 | 33-36 | 150 | |

| N38SH | 1.22-1.25 | 12.2-12.5 | 907 | 11.4 | 1592 | 20 | 287-310 | 36-39 | 150 | |

| N40SH | 1.25-1.28 | 12.5-12.8 | 939 | 11.8 | 1592 | 20 | 302-326 | 38-41 | 150 | |

| N42SH | 1.28-1.32 | 12.8-13.2 | 955 | 12.0 | 1592 | 20 | 318-342 | 40-43 | 150 | |

| N45SH | 1.32-1.36 | 13.2-13.6 | 995 | 12.5 | 1592 | 20 | 342-366 | 43-46 | 150 | |

| N48SH | 1.38-1.42 | 13.8-14.2 | 1035 | 13.00 | 1592 | 20 | 366-390 | 46-49 | 150 | |

| N50SH | 1.40-1.45 | 14.0-14.5 | 1043 | 13.1 | 1592 | 20 | 382-406 | 48-51 | 150 | |

| UH | N28UH | 1.04-1.08 | 10.4-10.8 | 764 | 9.6 | 1990 | 25 | 207-231 | 26-29 | 180 |

| N30UH | 1.08-1.13 | 10.8-11.3 | 812 | 10.2 | 1990 | 25 | 223-247 | 28-31 | 180 | |

| N33UH | 1.13-1.17 | 11.3-11.7 | 852 | 10.7 | 1990 | 25 | 247-271 | 31-34 | 180 | |

| N35UH | 1.17-1.22 | 11.7-12.2 | 860 | 10.8 | 1990 | 25 | 263-287 | 33-36 | 180 | |

| N38UH | 1.22-1.25 | 12.2-12.5 | 907 | 11.4 | 1990 | 25 | 287-310 | 36-39 | 180 | |

| N40UH | 1.25-1.28 | 12.5-12.8 | 923 | 11.6 | 1990 | 25 | 302-326 | 38-41 | 180 | |

| N42UH | 1.28-1.32 | 12.8-13.2 | 971 | 12.2 | 1990 | 25 | 318-342 | 40-43 | 180 | |

| N45UH | 1.32-1.36 | 13.2-13.6 | 1003 | 12.6 | 1990 | 25 | 342-366 | 43-46 | 180 | |

| N48UH | 1.38-1.42 | 13.8-14.2 | 1031 | 12.9 | 1990 | 25 | 366-390 | 46-49 | 180 | |

| EH | N28EH | 1.04-1.08 | 10.4-10.8 | 780 | 9.8 | 2388 | 30 | 207-231 | 26-29 | 200 |

| N30EH | 1.08-1.13 | 10.8-11.3 | 820 | 10.3 | 2388 | 30 | 223-247 | 28-31 | 200 | |

| N33EH | 1.13-1.17 | 11.3-11.7 | 860 | 10.8 | 2388 | 30 | 247-271 | 31-34 | 200 | |

| N35EH | 1.17-1.22 | 11.7-12.2 | 884 | 11.1 | 2388 | 30 | 263-287 | 33-36 | 200 | |

| N38EH | 1.22-1.25 | 12.2-12.5 | 923 | 11.6 | 2388 | 30 | 287-310 | 36-39 | 200 | |

| N40EH | 1.25-1.28 | 12.5-12.8 | 947 | 11.9 | 2388 | 30 | 302-326 | 38-41 | 200 | |

| N42EH | 1.28-1.32 | 12.8-13.2 | 970 | 12.2 | 2388 | 30 | 318-342 | 40-43 | 200 | |

| N45EH | 1.32-1.36 | 13.2-13.6 | 1003 | 12.6 | 2388 | 30 | 342-366 | 43-46 | 200 | |

| AH/TH | N28AH | 1.04-1.08 | 10.4-10.8 | 787 | 9.9 | 2786 | 35 | 207-231 | 26-29 | 230 |

| N30AH | 1.08-1.13 | 10.8-11.3 | 819 | 10.3 | 2786 | 35 | 223-247 | 28-31 | 230 | |

| N33AH | 1.13-1.17 | 11.3-11.7 | 843 | 10.6 | 2786 | 35 | 247-271 | 31-34 | 230 | |

| N35AH | 1.17-1.22 | 11.7-12.2 | 884 | 11.1 | 2786 | 35 | 263-287 | 33-36 | 230 | |

| N38AH | 1.22-1.25 | 12.2-12.5 | 915 | 11.5 | 2786 | 35 | 287-310 | 36-39 | 230 | |

| Grade | Temperature ℃ |

Temperature Coefficients | Unit | |

|---|---|---|---|---|

| of Br | of HcJ | |||

| N Serie | 20℃~100℃ | -0.090~-0.124 | -0.70~-0.82 | %/℃ |

| M Serie | 20℃~100℃ | -0.090~-0.124 | -0.65~-0.80 | %/℃ |

| H Serie | 20℃~100℃ | -0.090~-0.124 | -0.60~-0.75 | %/℃ |

| SH Serie | 20℃~100℃ | -0.090~-0.122 | -0.55~-0.70 | %/℃ |

| 20℃~150℃ | -0.095~-0.124 | -0.50~-0.65 | %/℃ | |

| UH Serie | 20℃~100℃ | -0.090~-0.120 | -0.53~-0.66 | %/℃ |

| 20℃~180℃ | -0.095~-0.122 | -0.48~-0.61 | %/℃ | |

| EH Serie | 20℃~100℃ | -0.090~-0.120 | -0.50~-0.62 | %/℃ |

| 20℃~200℃ | -0.095~-0.122 | -0.46~-0.58 | %/℃ | |

| TH Serie | 20℃~100℃ | -0.090~-0.120 | -0.47~-0.60 | %/℃ |

| 20℃~200℃ | -0.095~-0.122 | -0.45~-0.56 | %/℃ | |

| Curie Temperture Tc | 583~623 | K | ||

| Recoil Permeability μrac | 1.05 | - | ||

| Item | Value | Unit |

|---|---|---|

| Density | 7.40~7.70 | g/cm3 |

| Vickers Hardness(HV) | 500~700 | HV |

| Compressive Strength | 1000~1100 | MPa |

| Tensile Strength | 80~90 | MPa |

| Bending Strength | 150~400 | MPa |

| Thermal Conductivity | 8~10 | W/(m·K) |

| Young`s Modulus | 150~200 | GPa |

|

Electrical Resistivity (20℃) |

C∥1.4~1.6 | μΩ·m |

| C ⊥1.2~1.4 |

| Coating | Thickness (μm) |

Color | SST (hrs) |

PCT (hrs) |

Characteristics |

|---|---|---|---|---|---|

| White Zn | 4-15 | Bright blue | ≥24 | – | Poor corrosion resistance. |

| Color Zn | 4-15 | Shining color | ≥48 | – | Corrosion resistance is better than white Zn. |

| NiCuNi | 5-20 | Bright silver | ≥48 | ≥48 | Most regular used multi-layer coating. Excellent humidity and salt spray resistance. |

| Aluminum | 2-15 | Bright silver | ≥24 | ≥24 | Noticeable coating. |

| Epoxy | 10-30 | Black/Grey | ≥72 | ≥72 | Excellent humidity and salt spray resistance. Superir binding force. |

| Parylene | 5-20 | Colorless | ≥96 | – | Excellent humidity, salt spray, corrosive vapors, and solvents resistance. Free of pore. |

| Phosphating | 1-3 | Dark grey | – | – | Temporary protection. |

Sintered neodymium magnets are anisotropic materials - they have a preferred direction of magnetization locked into their structure. So the magnets can only be magnetized in one axis - any attempt to magnetize in another axis results in very little performance. Each sintered neodymium magnet has a direction of magnetization.

| Shape | Magnetization Direction | |

|---|---|---|

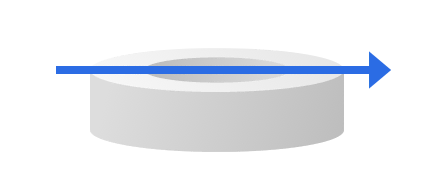

| Block |  |

Height |

| Cylinder/Disk |  |

Axial |

|

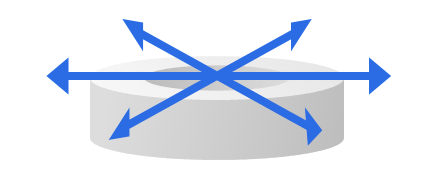

Diametral | |

| Ring |  |

Axial |

|

Diametral | |

|

Radial | |

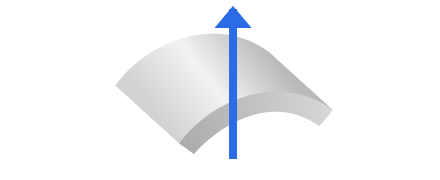

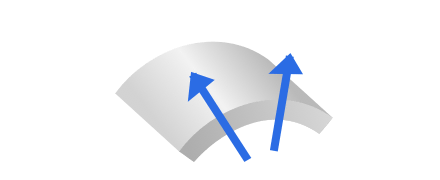

| Segment |  |

Diametral/Parallel |

|

Radial | |

Die-pressed sintered magnets usually need to be ground. The tolerance after grinding is normally ± 0.05 mm; from case to case, values up to ± 0.02 mm are possible. For tighter tolerances we would have to review the shape to inform you of the tolerances could achieve.

Bonded neodymium magnets have high dimensional accuracy, magnetic uniformity and consistency. They can be divided into compression molding NdFeB and injection molding NdFeB according to the processing methods.

Bonded neodymium magnets are usually compact isotropic magnets, they can be magnetized multi-polar and made into complex shapes which are difficult to be realize on sintered neodymiunm magnets and have tight tolerances, no need for further mechanical machining.

Bonded neodymiunm magnets are widely used in computer hard disk drive and optical disk drive, printer / copier motor and magnetic roller, energy saving home appliances, consumer electronics and control components etc.

| Grade | Residual magnetic flux density Br |

Intrinsic coercive force HcJ |

Coercive force HcB |

Maximum energy product (BH)max |

Work Temperature Tw |

Average Temperature Coefficients of Br |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| T | KGs | KA/m | KOe | KA/m | KOe | kJ/m³ | MGOe | ℃ | %/℃ | ||

| Compression Molding NdFeB | BNP-2 | 300-400 | 3.0-4.0 | 240-320 | 3.0-4.0 | 480-640 | 6.0-8.0 | 24-32 | 3.0-4.0 | 160 | -0.11 |

| BNP-4 | 400-500 | 4.0-5.0 | 240-320 | 3.0-4.0 | 560-720 | 7.0-9.0 | 32-48 | 4.0-6.0 | 160 | -0.11 | |

| BNP-6 | 500-600 | 5.0-6.0 | 320-400 | 4.0-5.0 | 560-720 | 7.0-9.0 | 48-60 | 6.0-7.5 | 160 | -0.11 | |

| BNP-8 | 600-680 | 6.0-6.8 | 360-440 | 4.5-5.5 | 640-800 | 8.0-10.0 | 60-72 | 7.5-9.0 | 160 | -0.11 | |

| BNP-8L | 600-680 | 6.0-6.8 | 400-480 | 5.0-6.0 | 640-800 | 8.0-10.0 | 64-72 | 8.0-9.0 | 160 | -0.11 | |

| BNP-8H | 600-660 | 6.0-6.6 | 400-480 | 5.0-6.0 | 1040-1360 | 13.0-17.0 | 64-72 | 8.0-9.0 | 180 | -0.10 | |

| BNP-8SR | 620-680 | 6.2-6.8 | 400-480 | 5.0-6.0 | 800-1120 | 10.0-14.0 | 68-76 | 8.5-9.5 | 180 | -0.10 | |

| BNP-10 | 690-730 | 6.8-7.3 | 400-480 | 5.0-6.0 | 640-800 | 8.0-10.0 | 76-84 | 9.5-10.5 | 160 | -0.10 | |

| BNP-10H | 700-750 | 7.0-7.5 | 440-520 | 5.5-6.5 | 720-840 | 9.0-10.5 | 80-88 | 10.0-11.0 | 160 | -0.10 | |

| BNP-12 | 720-770 | 7.2-7.7 | 440-520 | 5.5-6.5 | 720-800 | 9.0-10.0 | 88-96 | 10.0-12.0 | 160 | -0.10 | |

| BNP-12H | 740-800 | 7.4-8.0 | 440-520 | 5.5-6.5 | 760-880 | 9.5-11.0 | 88-96 | 11.0-12.0 | 160 | -0.10 | |

| BNP-12L | 760-810 | 7.6-8.1 | 400-480 | 5.0-6.0 | 480-640 | 6.0-8.0 | 88-96 | 11.0-12.0 | 150 | -0.12 | |

| BNP-13L | 780-830 | 7.8-8.3 | 400-480 | 5.0-6.0 | 480-640 | 6.0-8.0 | 88-104 | 11.0-13.0 | 150 | -0.12 | |

| Injection Molding NdFeB | BNI-3 | 340-450 | 3.5-4.5 | 200-280 | 2.5-3.5 | 400-600 | 5.0-8.0 | 20-28 | 2.5-3.5 | 120 | -0.11 |

| BNI-4 | 400-500 | 4.0-5.0 | 240-320 | 3.0-4.0 | 560-720 | 7.0-9.0 | 32-48 | 4.0-6.0 | 120 | -0.11 | |

| BNI-5 | 450-550 | 4.5-5.5 | 304-360 | 3.8-4.5 | 640-800 | 8.0-10.0 | 36-44 | 4.5-5.5 | 120 | -0.11 | |

| BNI-6 | 500-600 | 5.0-6.0 | 328-384 | 4.1-4.8 | 640-800 | 8.0-10.0 | 44-52 | 5.5-6.5 | 120 | -0.11 | |

| BNI-7 | 550-650 | 5.5-6.5 | 344-400 | 4.3-5.0 | 640-800 | 8.0-10.0 | 52-60 | 6.5-7.5 | 120 | -0.12 | |

| BNI-5SR | 450-550 | 4.5-5.5 | 320-400 | 4.0-5.0 | 880-1120 | 11.0-14.0 | 36-44 | 4.5-5.5 | 180 | -0.11 | |

| BNI-6SR | 500-600 | 5.0-6.0 | 320-400 | 4.0-5.0 | 800-1120 | 11.0-14.0 | 44-52 | 5.5-6.5 | 180 | -0.11 | |

The above mentioned data of magnetic properties and physical properties are given at room temperature (20℃).

The max working temperature of magnet is changeable due to length-diameter ratio, coating thickness and other environment factors.

Additional grades are available. Please contact us for information.

Magnetic assemblies are permanent magnets which are bonded to other permanent magnets or a different carrier material. Magnetic assemblies are important links to realize the functions of magnetic materials in the form of products or semifinished products made of magnetic materials, metal, nonmetal and other materials, such as motor rotors, sensors, filters, magnetic lifters, magnetic separators and magnetic pumps etc.

MagnetSearcher are not only a supplier of magnets but also your competent partner for the development and manufacture of advanced components and magnet assemblies. To provide you with this service we simply require your initial design sketches and specification profile describing the required function of the magnet assembly, the acceptable dimensions, the thermal and environmental conditions, and the electrical limiting conditions. Or you can simply contact us directly, and we will provide you with expert assistance.